After selection of your ZIP code, we designate the relevant staff to attend to you at once.

After selection of your ZIP code, we designate the relevant staff to attend to you at once.

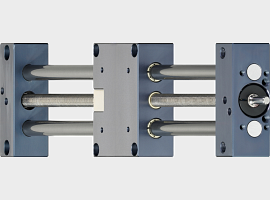

drylin® drive technology is based on the plain bearing principle instead of recirculating ball bearing systems. This results in much less noise and vibration. For you as the operator, the application with the linear unit is up to four times quieter.

drylin® drive technology distinguishes itself from its metallic counterparts not only with its technical advantages, such as freedom from lubrication and maintenance, but also costs up to 30% less. The linear drives of the drylin® ECON series are particularly cost-effective.

The use of cement creates a high level of dust load in the 3D concrete printer, which the products have to withstand. Furthermore, the longest possible service life and fast maintenance are required. Our bearing solutions and lubrication-free linear drives ensure a long service life despite dirt and contamination.

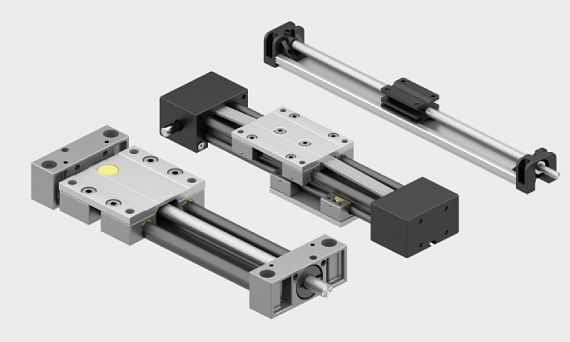

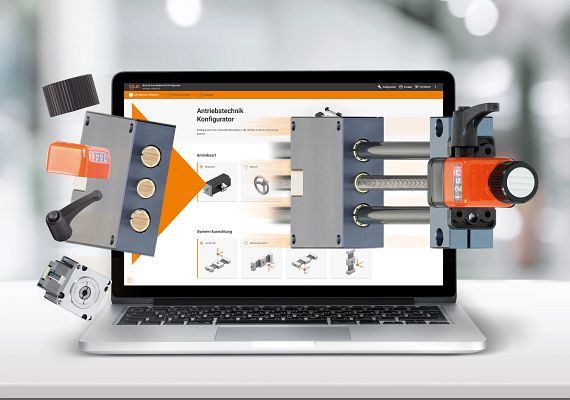

Toothed belt drives offer high acceleration and repeatability. They are therefore particularly suitable for pick-and-place machines, packaging systems, 3D printers and other applications where fast and precise positioning is required.

Lead screw drives offer high load capacity, precision and power transmission. They are therefore well suited for CNC milling, laser marking machines, machine tools and robotics applications. The lead screw drive ensures strong and accurate positioning.

Rack and pinion drives offer a combination of high speed, precision and load capacity. Applications for linear drives with gear rack can be found in material handling, packaging, assembly line automation, and other areas where rapid, accurate positioning over longer distances is required.

You can also use our ready-to-install linear modules for motorised lead screws drives. Thanks to the direct lead screw support in the motor, which is connected directly to your new linear module and therefore does not require a motor flange or coupling, up to 35% installation space can be saved with the drive elements, depending on the version.

What accessories are available for linear axes?

Monday to Friday from 7 am - 8 pm.Saturdays from 8 am- 12 pm.

24h