After selection of your ZIP code, we designate the relevant staff to attend to you at once.

After selection of your ZIP code, we designate the relevant staff to attend to you at once.

approx. ±10° torsion per chain link

High tensile strength due to ball-and-socket joint

Fiber rod option for partial directional control and reinforcement

No support elements such as steel cables, springs etc. are necessary

Diverse range of accessories

Optional retraction systems reliably guide the 3D e-chains® along the robot arm and dependably prevent loop formation

TRC - Safe, enclosed, chip-repellent

Smooth and robust exterior against interfering edges

High torsion stability

Can be arbitrarily shortened or extended

3 to 6 axes at robots

Multi-axis machine tools

Wet and cold cells

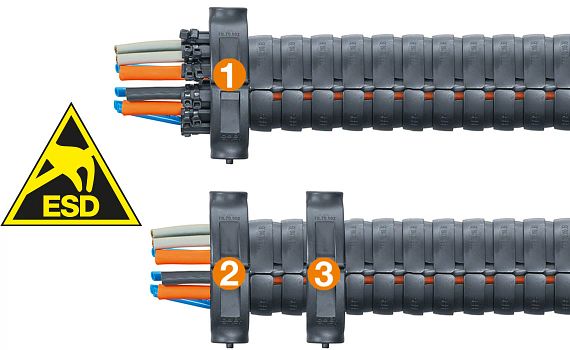

Painting applications and ESD

Sand and dust exposure

Linear motors

General mechanical engineering, etc.

In contrast to temporary conductive surface coatings or volatile incorporated antistatic agents, the additives used offer long lasting and maintenance-free conductivity. If individual e-chain components offer conductivity, this is not sufficient: the whole e-chain® from one end to the other must have continuous conductivity. All products in this catalogue are optimised in this regard and the continuous conductivity is measured and documented prior to delivery with 100% testing.

Only e-chains® that have passed this test are provided with the test seal and delivered. The colour of the triflex R chains is special because they are not slate grey (≈RAL7015) but still black, similar to ≈RAL9004. Unfortunately, this makes it somewhat more difficult to distinguish from standard materials. However, this is clearly defined via the material stamp.