After selection of your ZIP code, we designate the relevant staff to attend to you at once.

After selection of your ZIP code, we designate the relevant staff to attend to you at once.

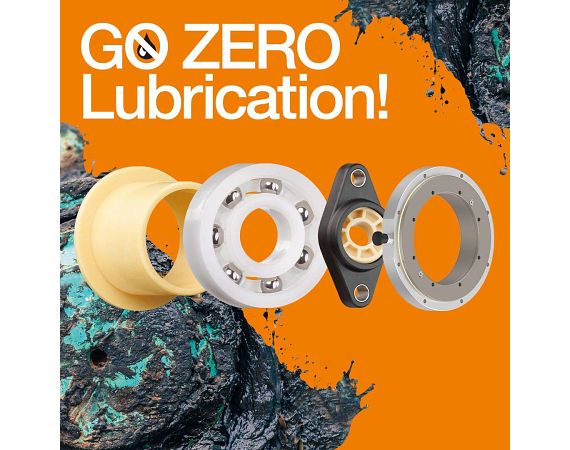

What do our iglidur plain bearings, xiros ball bearings, igubal spherical bearings and iglidur PRT slewing ring bearings have in common?

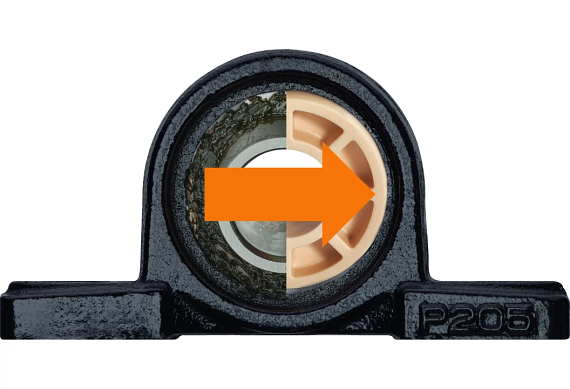

Compared to bearings made of solid metal, they are up to 80% lighter, vibration-dampening, maintenance-free and self-lubricating. This not only saves time and money, but also protects the environment.

A study by RWTH Aachen is the first to show the enormous savings potential of self-lubricating plastic bearings in terms of costs for lubricants, personnel and maintenance.

Discover our product range and benefit from the unique specifications of our bearing products!

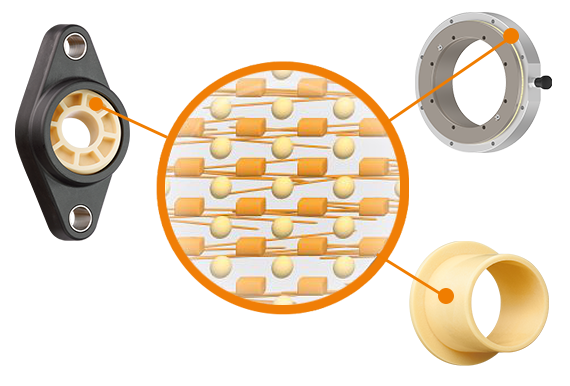

Our iglidur materials are an impressive example of progress made in materials science and tribology. By integrating solid lubricants directly into the material, they offer an excellent solution for applications that require reliable lubrication without regular maintenance.

The microscopically small particles ensure consistent lubrication for the entire service life of the material. This leads to a significant reduction in maintenance costs and increases operating efficiency. In addition, the predictability of the service life allows for precise planning and forecasting of maintenance intervals, which is invaluable for the industry.

The practical tests in our 4,000m² test laboratory, which confirm the durability of these materials, are further proof of their reliability and performance in demanding environments.

| Cost savings with 200 pieces | ||

|---|---|---|

| Spherical ball | igubal JEM | |

| Costs for 200 pieces | €1,350 | €300 |

| Estimated service life | 1 year | 4 years |

| Costs for lubricants (per year) | €45 | €0 |

| Hourly time required for lubrication (every year): 3 min. per bearing x 24 times every year x 200 bearings | 240hrs | 0hrs |

| Hourly rate per employee (€30/hr) x lubrication (240hrs) | €7,200 | €0 |

| Total annual costs | €8,595 | €75 |

| Annual savings | €8,520 |

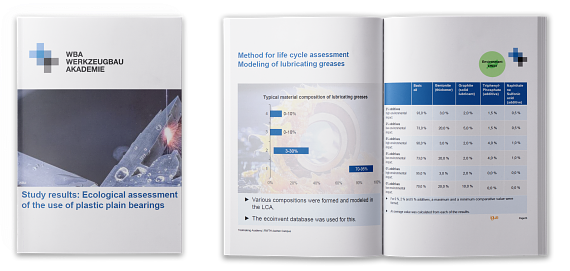

An independent study commissioned by igus quantifies the ecological and economic benefits of self-lubricating plastic bearings for the first time. It was carried out by the Werkzeugbau Akademie, a research company that works on the RWTH Aachen Campus as part of one of Europe's largest research laboratories in the field of production technology, together with the Fraunhofer Institute, among others.

As part of the study, expert interviews were conducted with nine companies from the automation technology, construction machinery, agricultural, food, packaging and bottling industries. The participants include CNH Industrial, Heineken and Krones AG.