After selection of your ZIP code, we designate the relevant staff to attend to you at once.

After selection of your ZIP code, we designate the relevant staff to attend to you at once.

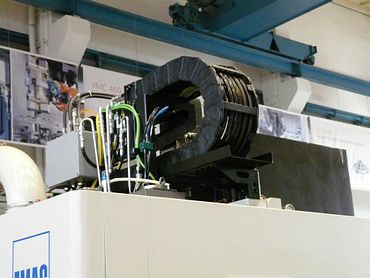

In industrial applications, core ruptures or broken shields are a hazard. This often causes machine downtime. igus designs its chainflex cables with mechanically high-quality copper conductors in optimised pitch length to avoid such stoppages. This core structure provides a high load capacity compared to conventional motor cables. From a core cross section of 10mm² it is recommended to switch to single cores for energy chain systems, as these can be used in a smaller installation space, which also benefits the mechanical design of the entire energy chain system.

Cost-effectiveness and compactness are the two primary characteristics that constitute the advantage of a single core over a multicore motor cable. Single cores can be produced at significantly lower cost than the multicore alternative. The small diameter allows faster processing, which ultimately translates to more favourable production costs.

In addition to lowering costs, they also take up less space, which is important when installation space is tight. Both factors make the use of single cores in energy chains in different applications especially attractive.